AUS-ROV delivers professional subsea inspection, engineering consulting, and spatial data acquisition services across Australia and the Pacific. Trusted by operators across the energy, water, mining, oil and gas, maritime, civil, construction, and defence sectors, we provide technically rigorous underwater solutions tailored to the demands of each industry and environment.

Specialising in:

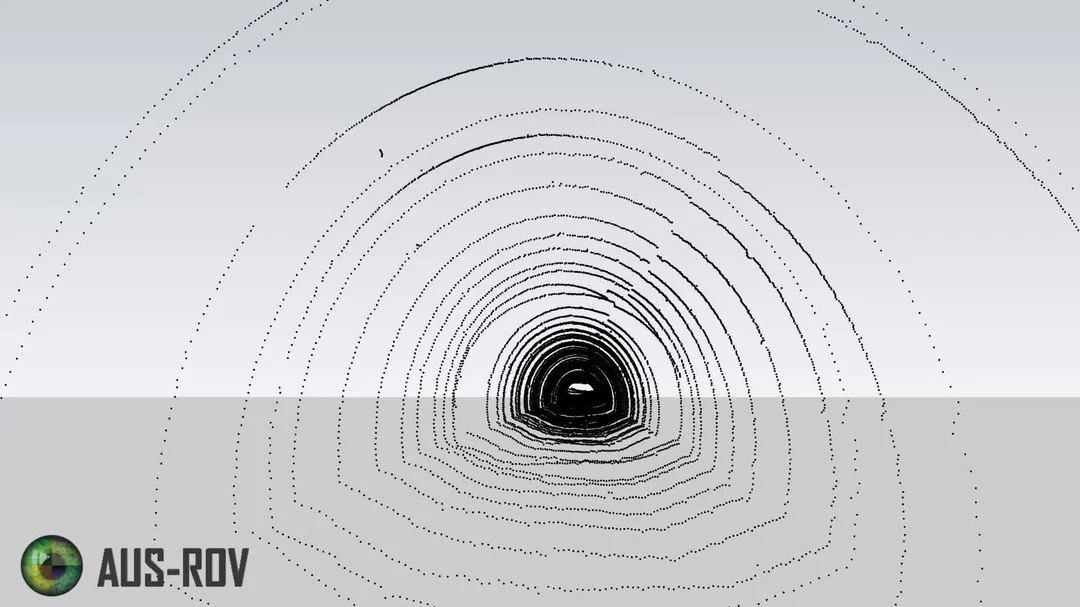

10km + Long Distance Tunnel Inspection and 3D Survey

Wharf and Jetty Pile ROV Water Jet Blast, GVI, CVI, UT + CP

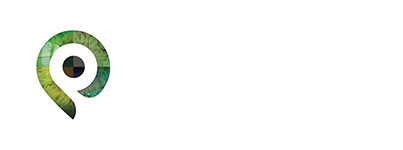

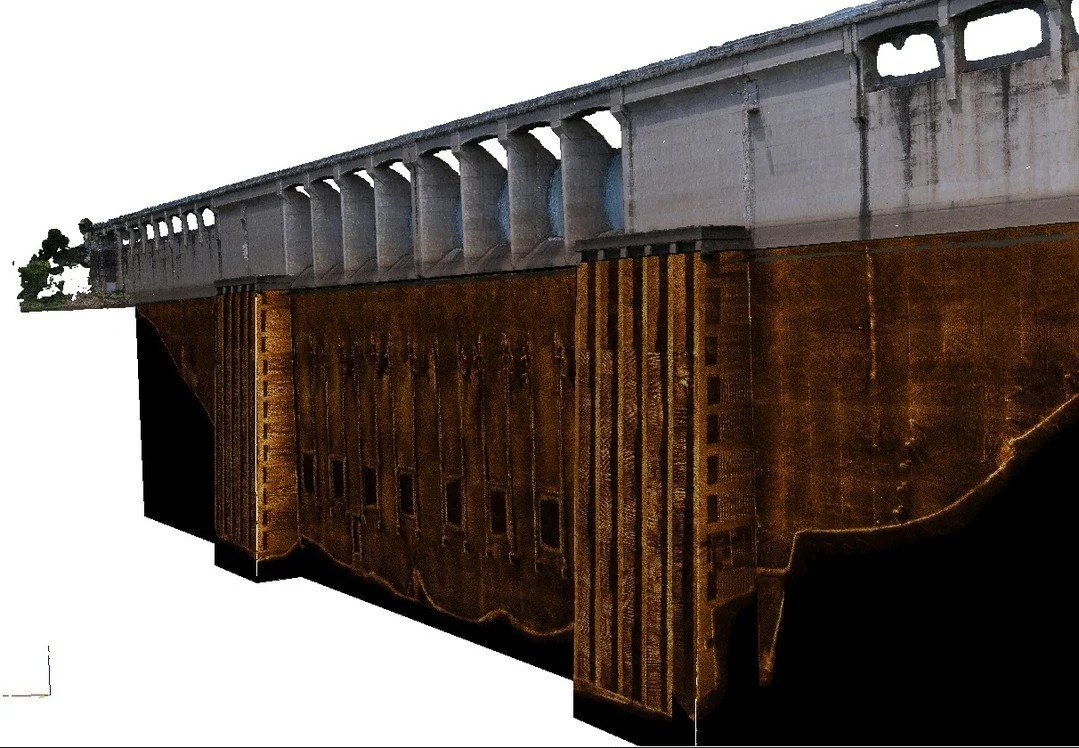

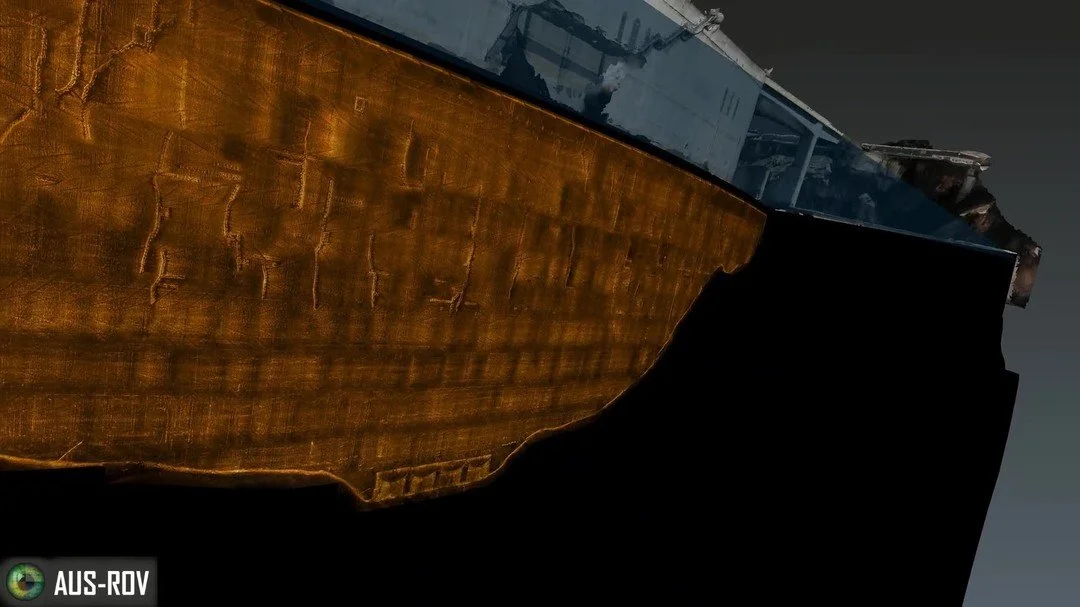

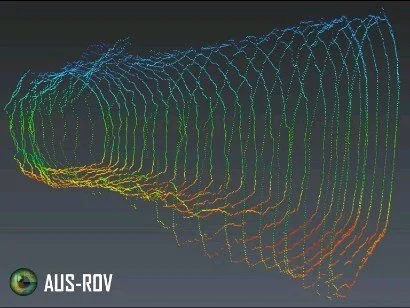

3D Photogrammetry and Underwater Laser Scanning

Desalination Plant and Power Station Water Infrastructure Inspection

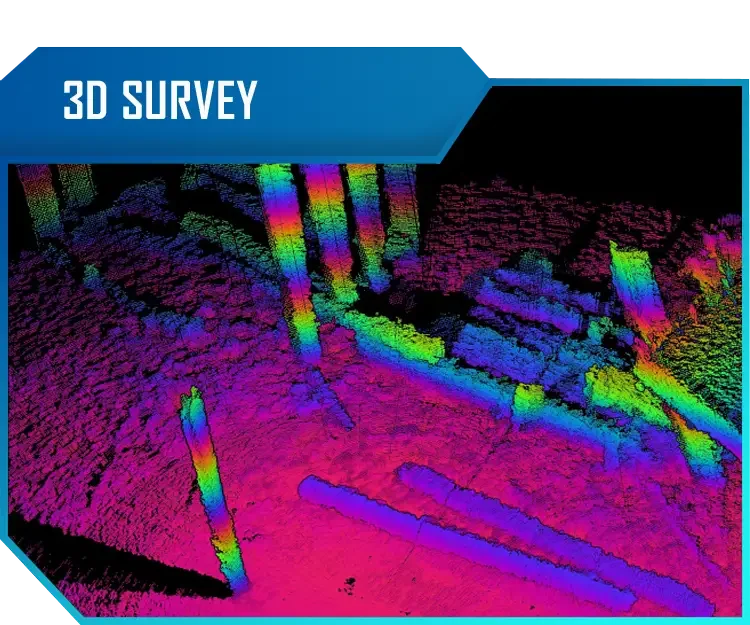

Subsea Pipeline Inspection and Depth of Burial Survey

High Resolution 2D Sonar Imaging Mosaics of Dams in High Turbidity

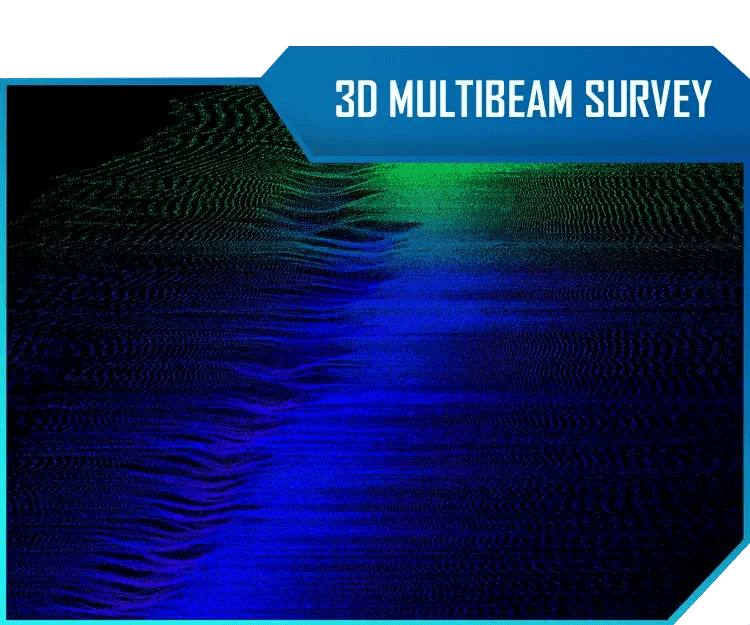

ROV and USV Deployed 3D Multibeam Sonar Data Acquisition

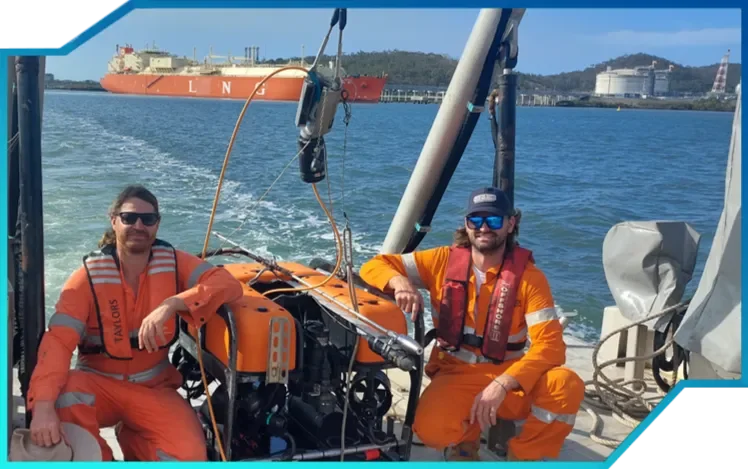

Founded in 2011 by the Jahnke Brothers, AUS-ROV is a family-owned company with a genuine passion for the ocean and a proven track record delivering ROV inspections, underwater surveys, and subsea engineering services safely and efficiently across Australia and the Pacific. From initial inspection through to final intervention, our team manages every phase of your project with technical precision and hands-on expertise.

Ready to discuss your project? Call us directly on 0412291870 or email inspections@aus-rov.com.au

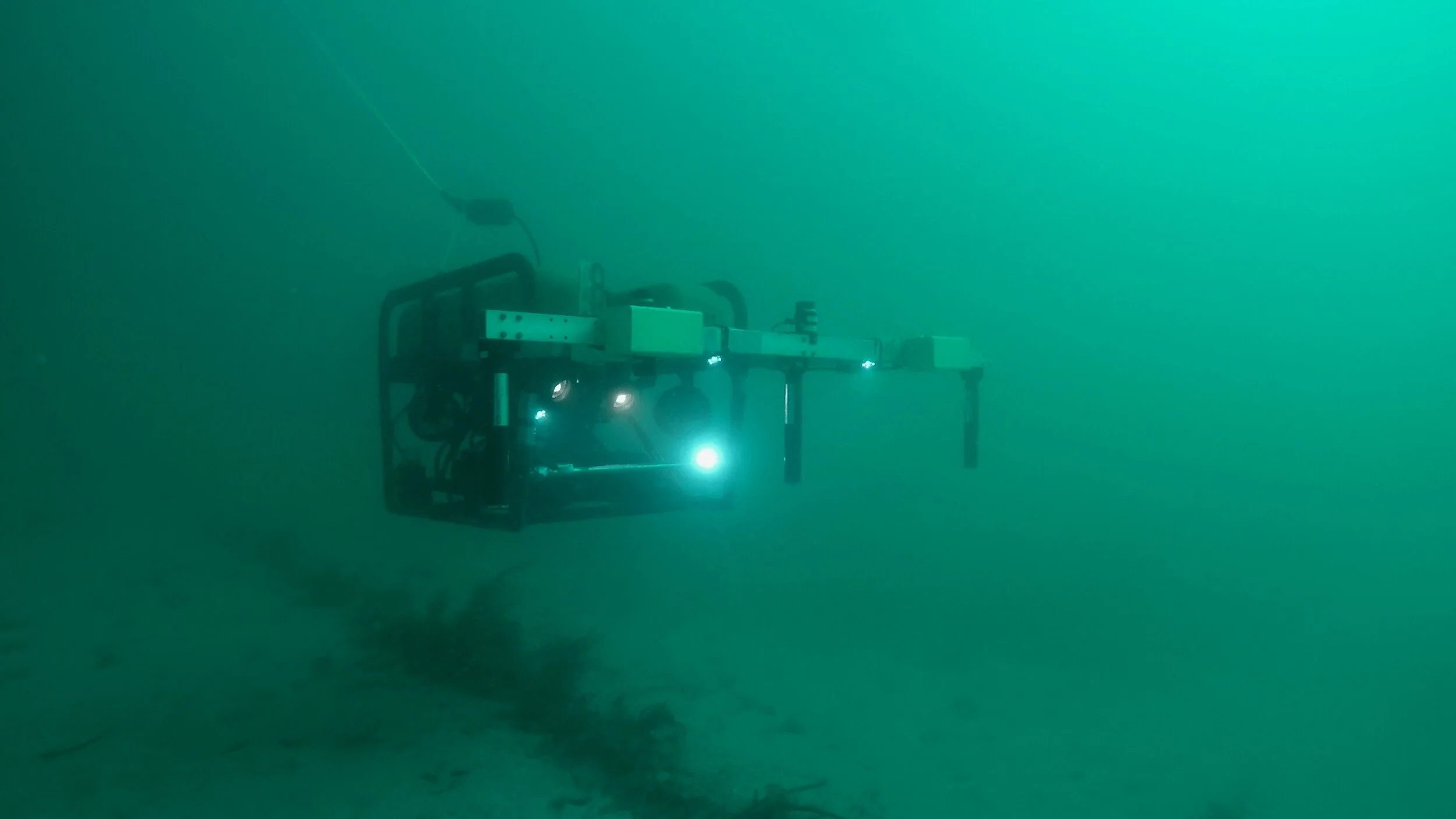

AUS-ROV is an Australian leader in remotely operated vehicle (ROV) inspection, survey, and intervention services for critical infrastructure across the mining, energy, and water sectors. Our advanced ROV technology enables safe, precise, and efficient access to confined or hazardous environments where human entry is not possible. With over 15 years of proven engineering expertise, AUS-ROV delivers high-resolution data and actionable insights to support asset integrity, maintenance planning, and operational reliability across subsea, mining, energy, marine, pipeline, tunnel, and industrial applications.

We provide remotely operated vehicle inspection services to the onshore and offshore mining, energy, and resources sectors. Our inspection project experience spans 15 years and extends across a multitude of industries and bespoke asset inspections.

AUS-ROV offers a unique spatial data acquisition service utilising single-beam and multi-beam sonars, underwater laser scanners and ultra-high definition UHD stereo cameras for processing 3D models and digital twins of underwater assets and environments.

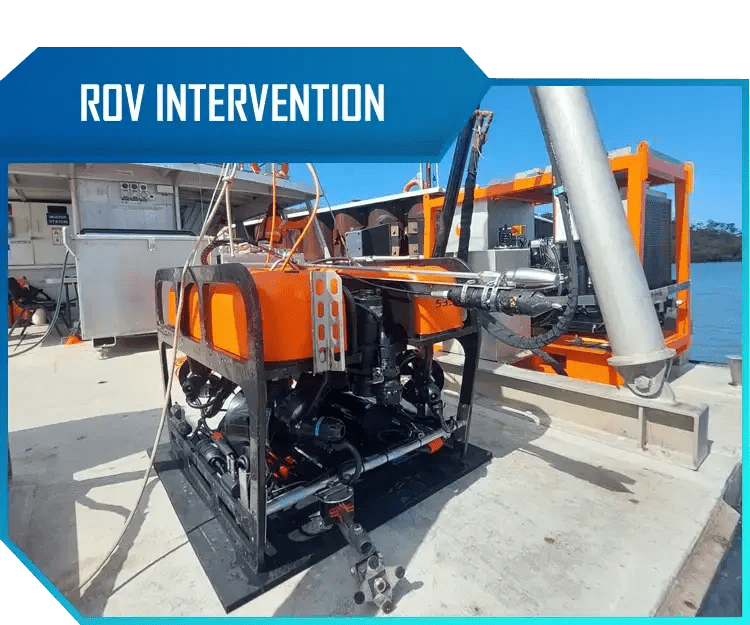

AUS-ROV offers bespoke intervention solutions tailored to the specific requirements of each project. Get in touch to discuss how we can support your next campaign.

Leveraging advanced remote technologies to help industry achieve zero-harm safety targets — delivering a reliable data acquisition platform that enables innovative inspection, survey, and intervention in challenging underwater environments.

-

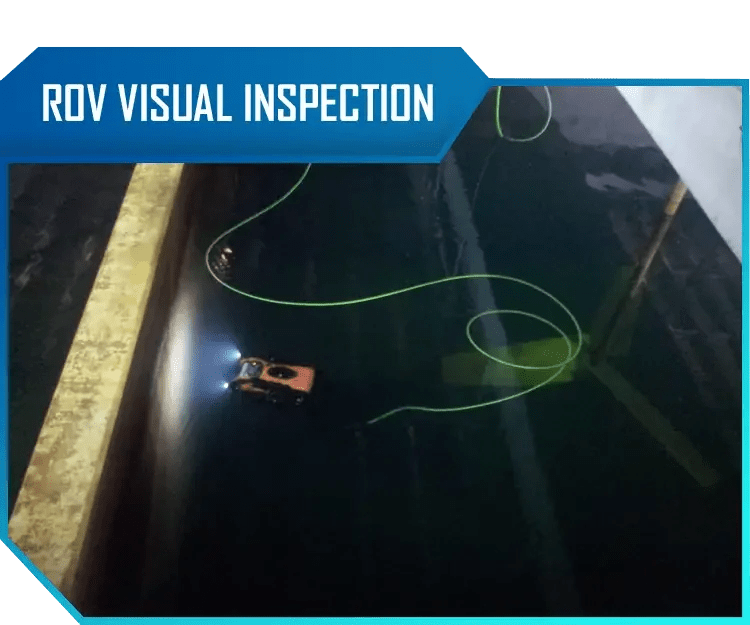

An underwater ROV inspection uses a remotely operated vehicle (ROV) fitted with cameras, lighting and (where required) sensors to capture visual and measurement data on submerged assets without sending divers underwater.

-

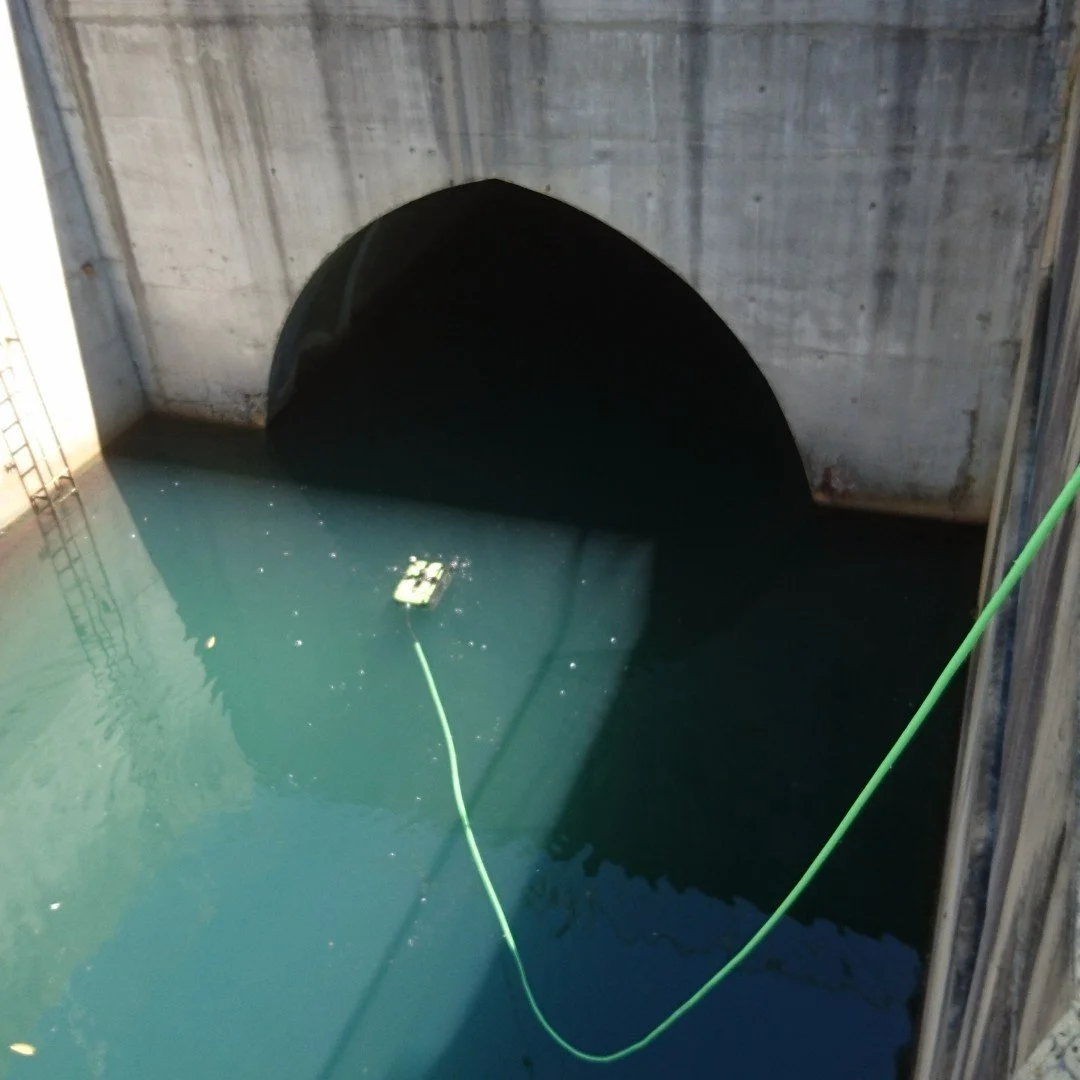

ROV inspection is often preferable where conditions are hazardous or restricted (poor visibility, depth, strong currents, confined spaces, contamination risk), or where repeatable inspection footage and spatial data are required with reduced safety exposure.

-

ROVs can inspect a wide range of underwater and confined assets including intake structures, trashracks, penstocks, tailraces, dams, tunnels, culverts, pipelines, outfalls, wharves and other marine or freshwater infrastructure.

-

Inspection range depends on the tunnel configuration, access, flow conditions and the selected ROV system. AUS-ROV can scope an appropriate long-distance tunnel inspection approach once asset constraints and required deliverables are confirmed. We currently support long distance tunnel inspection beyond 10km +

-

Typical deliverables include annotated video and imagery, defect observations, inspection logs, still image packs, and—where requested—georeferenced survey outputs such as sonar data products and spatial models.

Frequently Asked Questions

-

You can reach us anytime via our contact page or email. We aim to respond quickly—usually within one business day. Alternatively you can try your luck and give us a call on the mobile +61 412 291 870

-

Yes. AUS-ROV mobilises to sites across Australia and the Asia Pacific for underwater inspection, tunnel inspections and hydrographic survey projects, supporting energy and critical infrastructure operators.

-

AUS-ROV supports energy, water, marine, civil infrastructure, and industrial clients requiring underwater inspection, tunnel inspection, and hydrographic survey services.

-

es. Each project is scoped to suit the asset configuration, access constraints, water conditions, and required deliverables, ensuring data is fit-for-purpose and operationally practical.

-

Early engagement is recommended so inspection or survey methods can be aligned with project objectives, outage planning, safety considerations, and downstream engineering assessments.

AUS-ROV stands at the forefront of delivering customised underwater solutions, offering a comprehensive range of services across various disciplines to seamlessly execute turnkey projects for our clients. With a team of highly skilled professionals specialising in hydrographic surveying, electronic and mechatronic engineering, structural integrity engineering, naval architecture, geophysics, and ROV operations, we bring a wealth of expertise to every project. Our commitment to excellence ensures AUS-ROV is well-equipped to address the unique challenges of underwater environments, delivering tailored solutions that meet the highest standards of precision and reliability.

AUS-ROV's team spans hydrographic surveying, electronic and mechatronic engineering, structural integrity, naval architecture, geophysics, and ROV operations — a genuinely multidisciplinary group built over 15 years of solving unusual problems underwater.

Follow us on social media

AUS-ROV considers the health, safety and well-being of everyone, including the communities in which we do business, to be of utmost importance when planning and delivering ROV Projects.

The health, safety and wellbeing of our people and the communities we work within is the first consideration in planning and delivering every project.

HEALTH AND SAFETY

All AUS-ROV operations are governed by a zero-harm environmental policy, ensuring the ecosystems we work within are not negatively impacted by our activities.

ENVIRONMENT

Our personnel bring extensive marine operations experience to every job — and a professional yet personable approach that consistently produces the right outcomes for our clients.

QUALITY

Over 15 years, AUS-ROV has built lasting relationships with clients across Australia and the Pacific. Here's what some of them have to say.